Knife Edge Repair

Serialized Tab Data

Home › Repair Specifications › Knife Edge Repair

Knife Edge Repair

GENERAL KNIFE EDGE REPAIR SPECIFICATION:

This specification applies to the following types of trench shields:

3M, 4L, 4M, 6M, 8M, T, E, N, K, and LD

SPECIFICATIONS:

- All welding shall be performed according to the Structural Welding Code for Steel – AWS D1.1-90

- A certified welder shall perform all welding.

- 70,000 psi welding rod or wire shall be used to complete the welds.

- 3/16″ steel sheet with a 55,000 psi minimum yield strength shall be used to replace the skin plate cut away from the collars

PROCEDURE

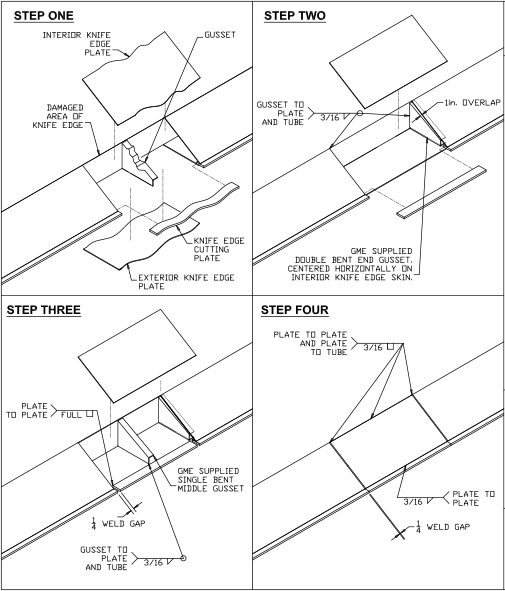

- Inspect damaged area of knife in order to determine extent of damage and material needed for repair. Cut out interior skin of knife edge and if necessary remove exterior skin as well.

- Once damaged material has been removed. Prepare surface for welding. Place GME supplied End Gussets at each end of opening show in Step 2. Place 1/2 Plate 2-1/2 x Length cutting edge as needed and weld into place.

- Weld GME supplied center gusset in the middle of opening, weld as shown. Place interior skin on top of the center gusset and overlapping the end gussets.

- Fully weld skin plate to horizontal tubing and end gussets, as well as along bottom cutting edge.

NOTE

In accordance with OSHA regulations, a Registered Professional Engineer must observe and provide written conformation that the above specification has been followed as authorized by the factory or the Tabulated Data will no longer be valid.