Collar Repair

Serialized Tab Data

Home › Repair Specifications › Collar Repair

General Collar Repair

GENERAL COLLAR REPAIR SPECIFICATIONS

This specification applies to the following types of trench shields:

3M, 4L, 4M, 6M, 8M, T, E, N, K, and LD

SPECIFICATIONS:

- All welding shall be performed according to the Structural Welding Code for Steel – AWS D1.1-90

- A certified welder shall perform all welding.

- 70,000 psi welding rod or wire shall be used to complete the welds.

- 3/16″ steel sheet with a 55,000 psi minimum yield strength shall be used to replace the skin plate cut away from the collars.

- The Replacement Collar shall be manufactured by GME.

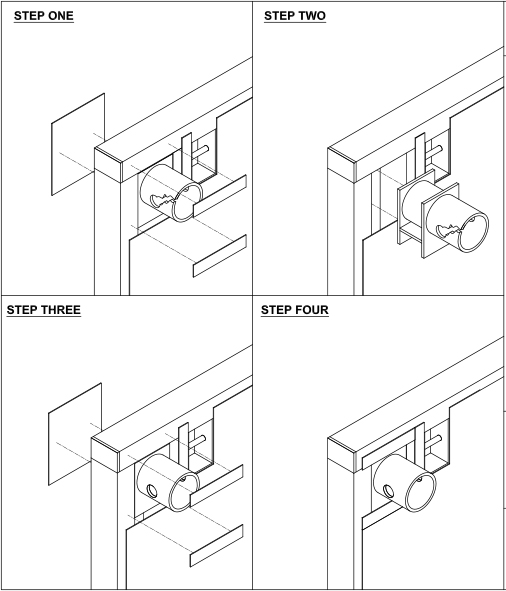

PROCEDURE

- Trim the skin plate around collar on both sides of the shield.

- Cut old collar out, being careful not to cut into the vertical tubes. Clean the area to be welded thoroughly with a wire brush or grinding wheel.

- Weld the replacement collar to the tubes in all accessible locations use a continuous 3/16″ fillet weld. The trench shield should be rolled over and the other side of the collar should be welded in the same manner to the vertical tubes.

- Replace the skin plate using the steel sheet specified above. Weld all around the new sheet with a 1/8″ fillet weld to prevent water and mud from entering the shield.

NOTE

In accordance with OSHA regulations, a Registered Professional Engineer must observe and provide written conformation that the above specification has been followed as authorized by the factory or the Tabulated Data will no longer be valid.