Strut Cart Roller Repair

Serialized Tab Data

Home › Repair Specifications › Strut Cart Roller Repair

Strut Cart Roller Repair

SPECIFICATIONS

- All welding shall be performed according to the Structural Welding Code for Steel – AWS D1.1-90

- A certified welder shall perform all welding.

- 70,000 psi welding rod or wire shall be used to complete the welds.

- 3/16″ steel sheet with a 55,000 psi minimum yield strength shall be sued to replace the skin plate cut away from the collars.

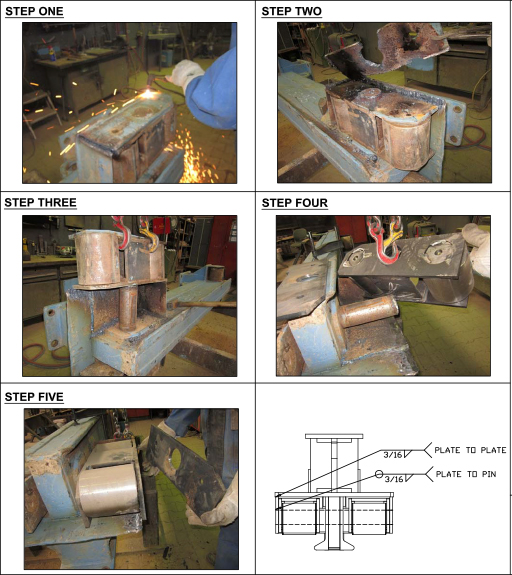

PROCEDURE

- Identify strut cart that needs to be repaired

- Carefully cut out the roller housing end plate making sure that the roller pin does not get damaged.

- Remove the roller assembly plate to expose the pivoting roller assembly. Prepare surfaces for welding.

- Put new pivoting roller assembly on roller pin. Note no welding required on the pivoting roller assembly. (this assembly is to move freely inside the housing unit)

- Weld replacement housing plate to the outside of the housing unit.