Linear Rail Repair

Serialized Tab Data

Home › Repair Specifications › Linear Rail Repair

Roller Assembly Restoration

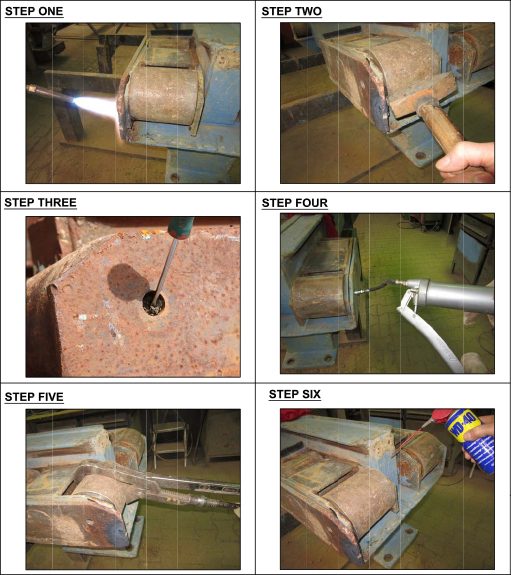

PROCEDURE

- Inspect the roller assembly for any damages that may prevent the roller assembly from rotating freely.

- Heat may be applied to any damaged areas in order to make the needed repairs.

- Clear any debris from grease fitting openings on outer plate.

- Apply 8-10 pumps of ngl1 grade @2 multi-purpose gun grease. (10mm x 1 straight grease fit)

- Large diameter pipe wrench or HD chain wrench to free up each roller.

- Apply spray lubricant or penetrating oil to assembly pin. Repeat as needed in order to free up roller assembly.

- If this procedure does not work please refer to repair procedure.