Stack Tube Relocation

Serialized Tab Data

Home › Repair Specifications › Stack Tube Relocation

Stack Tube Relocation

GENERAL STACK LUG RELOCATION SPECIFICATION:

This specification applies to the following types of trench shields:

3M, 4L, 4M, 6M, 8M, T, E, N, K, and LD

SPECIFICATIONS:

- All welding shall be performed according to the Structural Welding Code for Steel – AWS D1.1-90

- A certified welder shall perform all welding.

- 3/16″ steel sheet with a 55,000 psi minimum yield strength shall be used to replace the skin plate cut away from the collars.

- The Stack tube shall be manufactured by GME.

PROCEDURE

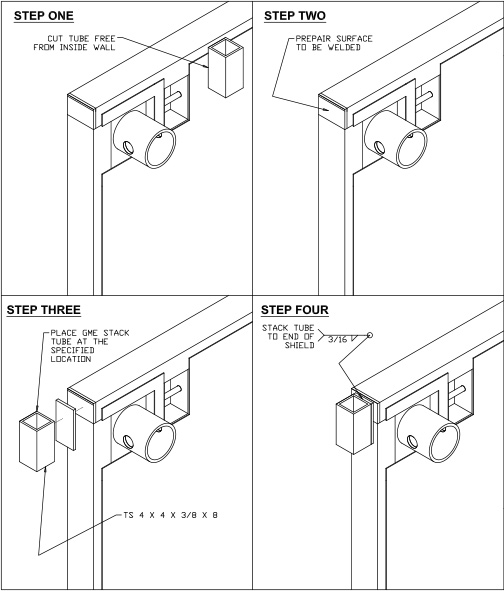

- Cut off GME stack tube location on the inside skin of the shield.

- Repair any holes on the skin that may have occurred during the cutting process. Once hole(s) are welded closed, clean the area thoroughly with a wire brush or grinding wheel.

- Clean the area to be welded thoroughly with a wire brush or grinding wheel.

- Weld the replacement stack tube to the end of the shield, using a all around 3/16″ fillet weld.

NOTE

In accordance with OSHA regulations, a Registered Professional Engineer must observe and provide written conformation that the above specification has been followed as authorized by the factory or the Tabulated Data will no longer be valid.