Top Tube Repair

Serialized Tab Data

Home › Repair Specifications › Top Tube Repair

Top Tube Repair

GENERAL TUBE REPAIR SPECIFICATION:

This specification applies to the following types of trench shields:

3M, 4L, 4M, 6M, 8M, T, E, N, K, and LD

| 4L, 4M, N, E | C5 x 9 CHANNEL |

| 6M, 6H, K | C7 x 12.5 CHANNEL |

| 8M, 8H, LD | C9 x 15 CHANNEL |

SPECIFICATIONS

- All welding shall be performed according to the Structural Welding Code for Steel – AWS D1.1-90

- A certified welder shall perform all welding.

- 70,000 psi welding rod or wire shall be used to complete the welds.

- C-Channel shall be Fy=50ksi material.

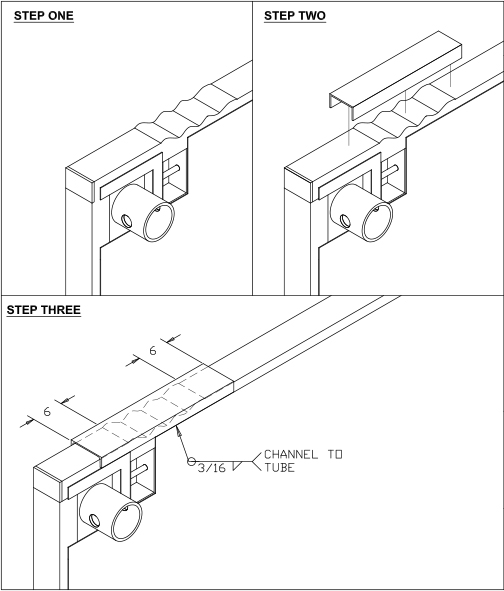

PROCEDURE

- Inspect tube make sure tube can be capped or formed back in place. If skin plate is damaged, consult factory.

- Determine length of the channel required. Overlap damaged area by a minium of six inches on each end.

- Weld channel to damaged tube using a continuous 3/16″ fillet weld as shown.